The circulation fluid heaters are particularly suitable for liquid heating such as water, superheated water, heavy fuel, fuel oils, oils and fluids and thermal heating of pressurized gas such as air, steam (superheater), nitrogen, hydrogen, methane, etc...

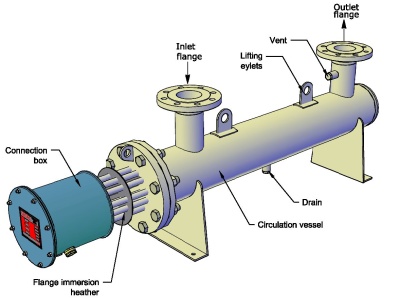

Specifically designed for each industrial application, circulation heaters consist of one or more heating elements. They can be hydraulically connected in series and / or in parallel to increase heating power. They are in accordance with the requirements of European Directive PED.

The material of the beam heating elements is selected in different stainless steel material to fit the fluid characteristics (corrosion) and its temperature. The shape and number of spacers are designed for optimum heat transfer. The beam heating, immersion depth is of max 3300mm, and can be equipped with temperature control device to improve specific watt density load (W/cm ²) according to parameters change such as flow, pressure, viscosity, fluid temperature, skin temperature,. ..

Made according to manufacturing codes for specified pressure and temperature (CODAP, ASME, TEMA, Stoomwezen ...), these units can achieve very high power (≥ 2000 kW) and able to monitor fluid rate, which is the main characteristic for excellent heat exchange.

The heaters subject to standard are conducted by the LCIE and conform to procedure EN60097-0.

GENERAL INFORMATION

APPLICATIONS

- Catalytic ovens

- Catalytic reactors

- Catalyst regeneration

- Systems analysis

- Separators

- Redox

- Desulfurization

- Démercurisation

- Overheating wax

- Ammonia production

- Oil heat

- Thermal spray oil

- Water tanks for fire fighting cons

- Bitumen tanker

- Sites methanol

- Refining

- pharmaceutical industry

ACHIEVEMENTS

Petrochemicals

Heater hydrogen 140-325 ° C

- 6x54KW 400 V - 12 bars

- DN125 PN25

- PED 97/23 risk category / CE III

- ATEX EExdIIC

Petrochemicals, fuel production

Superheater hydrogen at 618 ° C

- 82kW - 62kW - 36kW - 18KW

- ATEX EExdIIC

Petrochemicals

Natural gas heater at 96 ° C

- 380V 101KW

- 45 bars

- ASME VIII Div

- ATEX EExdIIC

Flange immersion heater

- compression station

- lube oil, 3kW

- ATEX EExdIIB

Petrochemicals

Oil heating at 25 ° C

- 500KW 660V - 13 bars

- DN500 PN20

- ASME XIII Div.1

- ATEX EExdIIC