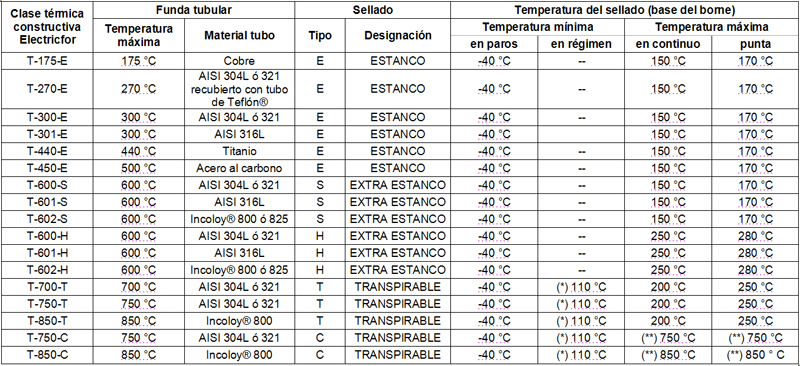

The aim of building thermal Escoin Santi classes is construction defining a type of resistance depending on the material of the sheath, its maximum allowable temperature and type of Sealed. These three characteristics, and especially the sheath material, should be chosen keeping in mind the work environment where resistance.

COVER MATERIALS

• AISI 304: stainless steel austenítico. Optimum weldability and has good corrosion resistance to Ambient temperature. Other properties of the type 304 are satisfactorily high temperature service (800° a 900°C) and good properties mecánicas.El type 304 contains low carbon content so that carbide precipitation is avoided for extended periods of high temperature; has a carbon content of 0,08% maximum for which he is considered a satisfactory material for most welding applications.

• AISI 304L: stainless steel austenítico. Optimum weldability and has good corrosion resistance to Ambient temperature. If kept for some time in the critical temperature range 450 at 850 ° C, a crystalline precipitation of chromium carbide can occur with consequent Intergranular corrosion.

• AISI 321: Components A AISI 304 is added a certain amount of titanium which has the effect of preventing the formation of chromium carbide and, consequently, prevents the phenomenon of Intergranular corrosion, making this particularly suitable material to use for prolonged periods of time in a critical temperature range. It has good resistance to carbon build up 800 °C.

• AISI 316L: Contains an addition of 2 ÷ 3% molybdenum which confers greater resistance to pitting (Pitting) and better performance than the above steel corrosion under tension. Carbon content of less than 0’03% which hinders the formation of chromium carbide, and increased resistance to Intergranular corrosion.

• INCOLOY® 800: stainless steel refractory with high nickel and chromium. Good resistance to carbon build up 1.100 °C. Has a high tensile strength and good corrosion resistance at high temperatures.

• INCOLOY® 825: This is a Alloy nickel-iron-chromium with additions of molybdenum and copper. It offers good resistance to both reducing and oxidizing acids, stress corrosion, sting and the Corrosion interstitial.

® Registered trademark of “The International Nickel Co.”

• COPPER (SF-Cu DIN 1787): Semi-noble and highly corrosion resistant metal nature waterfront.

• TITANIUM: Titanium is a metal member having a hexagonal close packed structure, It is hard, refractory and a good conductor of electricity and heat. It is highly resistant to corrosion. Corrosion resistance available is due to the phenomenon of passivation suffering (overlying an oxide is formed).

TYPES Sealed

• Sealed Watertight: this Sealed does not allow moisture penetration resistance, maintaining insulation values for more than five years. The temperature of the sheath and Sealed should not exceed 300 °C y 150 ° C respectively. If the temperature exceeds the sheath 300 ° C temperature or Sealed exceeds 150 ° C, insulation values decrease rapidly and leaks appear shortly.

• Sealed extra Watertight: this Sealed does not allow moisture penetration resistance while maintaining insulation values for more than ten years. In this case the temperature of the cover can reach 600 °C. If the temperature exceeds the sheath 600 ° C temperature or Sealed exceeds 150 °C / 250 °C (according to temperature class) insulation values decrease rapidly and leaks appear shortly.

• Sealed transpirable: When working resistance over 600 °C, it consumes oxygen. Si el Sealed does not allow entry thereof, resistance life is reduced to a 100 hours. Therefore it has been designed a Sealed allowing entry of air in sufficient quantities to allow proper breathing resistance. However, to perform a correct breathing, must be verified that the resistance stands at intervals over 5 minutes, at least 15% weather, and does not work without stopping over 8 followed hours. Stoppages can be perfectly the originating control means, as thermostats, etc.. as usual in most applications.

Due to the special conditions of this Sealed, to allow the air inlet, also allows moisture penetration, whereby the insulation can be lowered to values close to 1 MW and, when connecting, after prolonged unemployment, transient current leakage may occur. These leaks can reach 5 mA by Kilowatt during the transitional, to drop to values of 0.2 mA by Kilowatt to stabilize the temperature. To ensure that leaks away before reaching the temperature stabilization, and thus comply with the UNE-EN-60335, must ensure that the temperature of Sealed is at least 110 °C.

LIMITS OF USE OF HEATING ELEMENTS BLINDADOS

Temperature Funda tubular is measured with a thermocouple of fine wire with little Period, welded to shield resistance in the heat.

(*) In Sealed breathable leaks can reach up 5 mA by Kilowatt during heating, but on reaching the temperature regime leaks are within the values required by the standard, provided that the temperature Sealed reaches at least 110 °C. We therefore recommend not choose Sealed breathable unless absolutely necessary for the temperature reaches the Sealed or Shield.

(**) The maximum temperature of Sealed coincides with the maximum allowable temperature in Funda tubular. Anyway in the installation must be taken into account other temperature limitations such as the maximum temperature in the supply conductors, bounds, platinas, etc..

In the design of apparatus embodying the resistors should be noted that the temperature reached by the resistance can not dangerously affect other parts of the apparatus.

To ensure an acceptable life, is advisable to check the corrosion resistance of the sheath material into the environment that originates from the water heater. We remind you that even the stainless steel in drinking water, can easily corroded. For more information consult our technical sheet NTT-4101, or contact our Technical Sales Department.