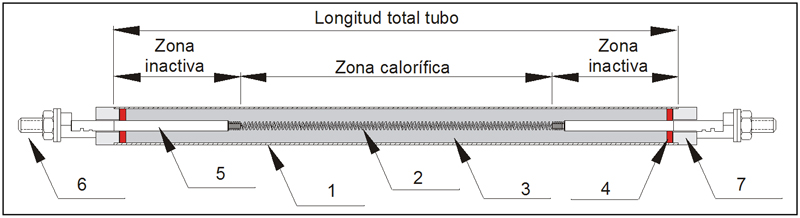

1.- Funda tubular

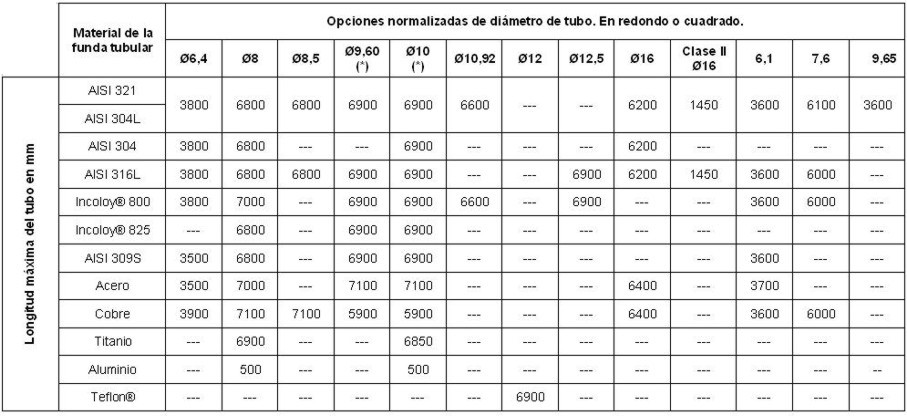

Varies depending on the material to be heated and the temperature of Use. See attached table where some of the most standard sheath materials, and the various methods of pipe diameters and lengths.

2.- Resistive Spiral

Alloy resistance wire Nickel chrome or other metals. Varies depending on the type of work that resistance is intended. The Resistive Spiral may be constituted by one, dos o tres hilos.

This element is the heat source.

3.- Granular insulator

Magnesium oxide electromelted the appropriate class of building thermal characteristics Santi Escoin. Once compacted by rolling or compression is achieved good Thermal Conductivity while the insulation is ensured Dielectric correct.

4.- Sealed

Protects against moisture penetration into the resistance.

Five types of sellados depending on class thermal constructive Santi Escoin:

– Sealed Watertight.

– Sealed extra Watertight.

– Sealed extra Watertight high temperature.

– Sealed transpirable.

– Sealed transpirable high temperature

5.- Output

In steel preniquelado, stainless steel AISI 303 o acero.

The internal output length determines the inactive zone of resistance.

6.- Borne connection

Different types of terminals for connection to the mains.

7.- Aislante borne

Ceramic feedthroughs or thermoplastic material to ensure isolation Dielectric between the output and Funda tubular.

PROGRAM COMPONENT MANUFACTURING TUBULARES BLINDADOS

• Longitudes hasta 1590 mm for all lengths.