In chemical industries, petrochemical, industrial processes, oil rigs and military installations materials which are stored, processed or produced in areas where the atmosphere is potentially explosive and explosion-proof heating elements which are needed.

From July of 2003 all teams with entry into service within the European Community must comply with the directive of obligation ATEX 94/9/EC. All equipment contained in this catalog are certified based on Directive ATEX 94/9/EC.

Overview

For the purposes of Directive 94/9/EC, an explosive atmosphere is defined as a mixture:

at) flammable substances in the form of gases, vapors, nieblas or polvos;

b) with air;

c) under atmospheric conditions;

d) in which, after ignition, combustion spreads to the entire unburned mixture (it should be noted that the combustion is not always consume all the dust, if any).

For an explosion to occur the following conditions must match:

- Presence of oxygen in the air.

- Presence of a flammable substance in a gas, steam, Niebla by polvo.

- A source of sufficient energy, as it can be an arc or a given temperature rise.

Understand atmospheric conditions when the temperature is between -20 ° C and 40 ° C and the pressure is in the Rank 0,8 bar a 1,1 bar

All electrical equipment to be installed in such atmospheres must be designed and constructed so that their energy output does not produce the expected explosion, what is this controlled.

The European Community has issued Directive ATEX 94/9/EC and regulations that require the user to assess the risk of explosion, taking into account the probability of occurrence of such atmospheres, its Degree Hazard, the presence of energy sources, processes and their interactions, the installation of equipment and its possible consequences.

If a risk exists, the user must:

- Prevent the formation of potentially explosive atmospheres. If this is not possible,

- Prevent ignition. If this is impossible,

- Reducing the impact of the explosion so that the risk is eliminated.

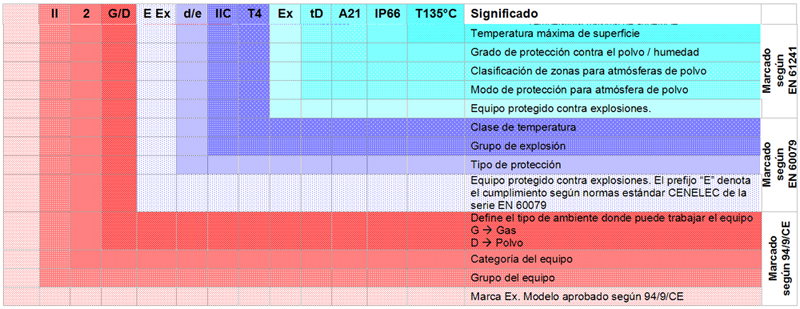

Marked ATEX

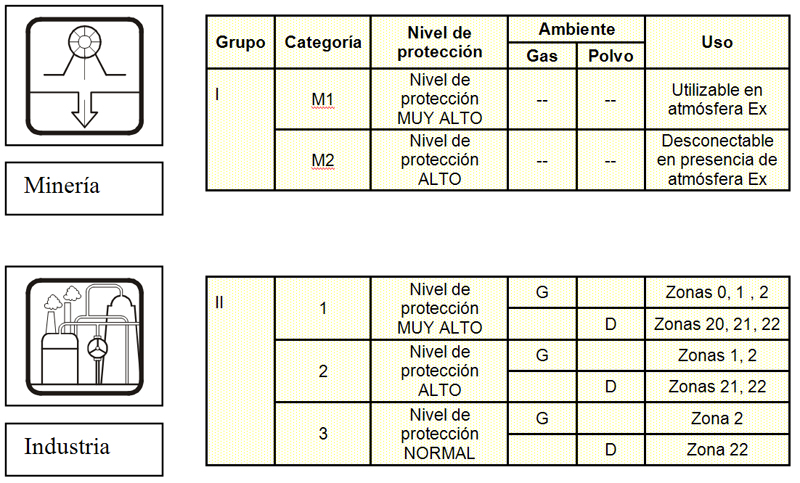

Group and category teams

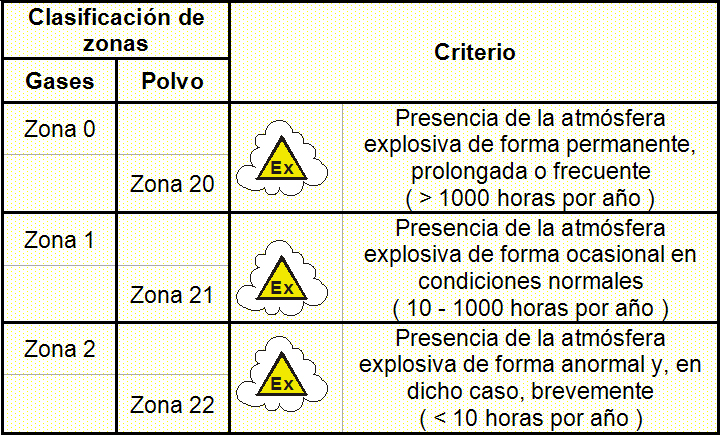

Classification of hazardous areas (According to EN 60079-10)

Explosive atmospheres are divided into zones. The classification depends on areas of the temporal and spatial probability of a hazardous explosive atmosphere appears.

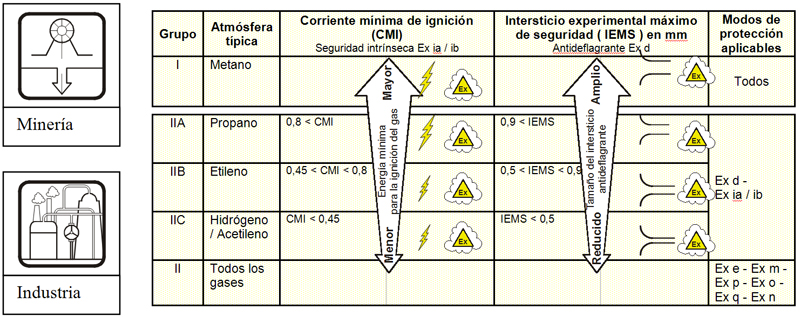

Groups gases

In the explosion groups first difference between Group I and Group II material: The electrical apparatus of Group I are used in mines with firedamp hazard occurrence.

For electrical equipment of Group II applies a new subdivision in explosion groups. This division depends on the transmission capacity of the ignition through a gap with a maximum width of security and longitude given

Note:

• An apparatus for gas group IIC is also suitable for Groups IIA and IIB.

• An apparatus for gas group IIB is also suitable for Group IIA.

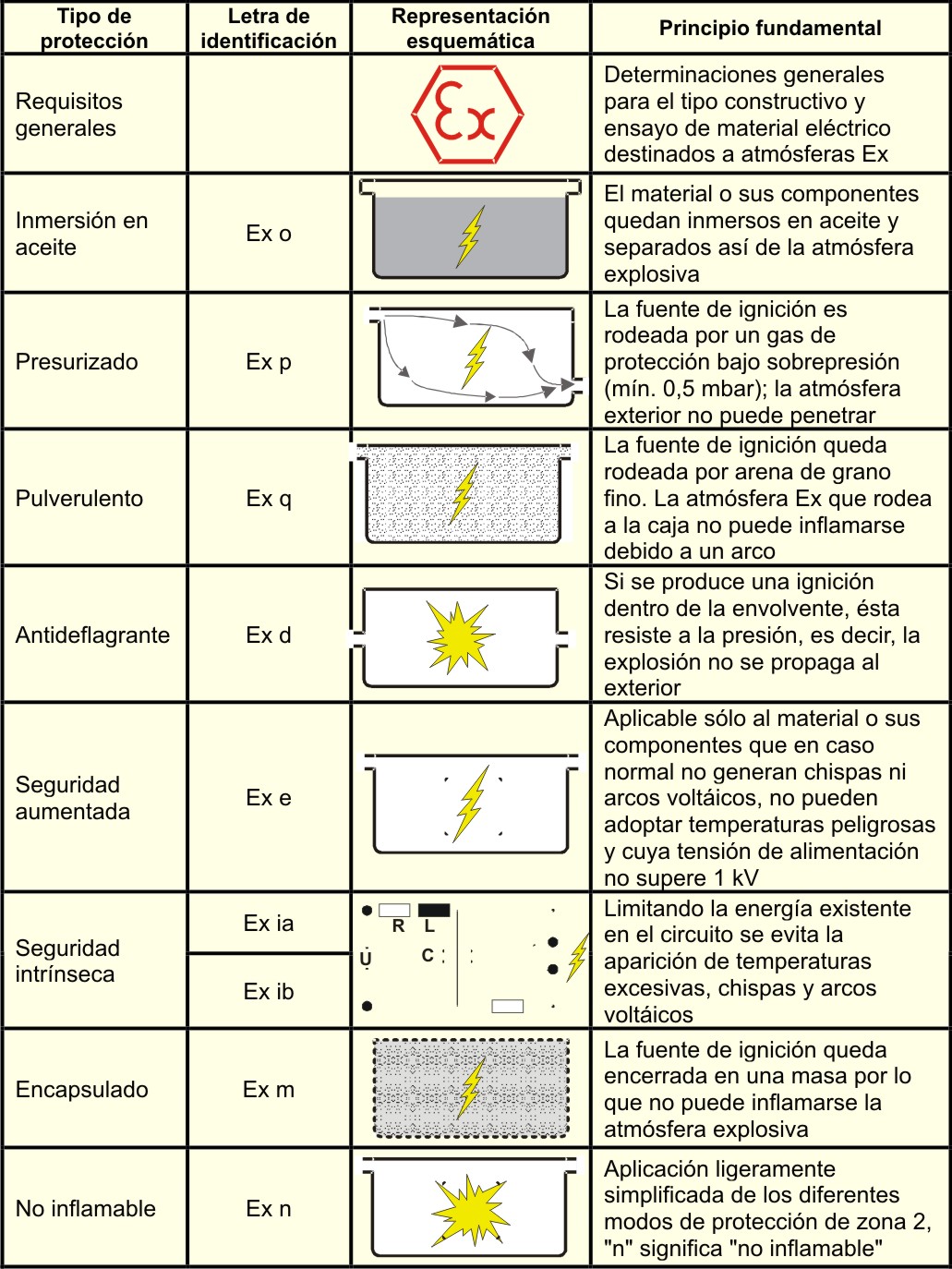

Modes of protection:

The Protection Modes are constructive and electrical measurements taken in the material to achieve protection against potentially explosive atmospheres.

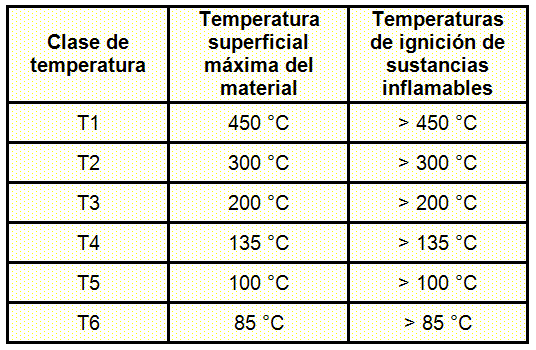

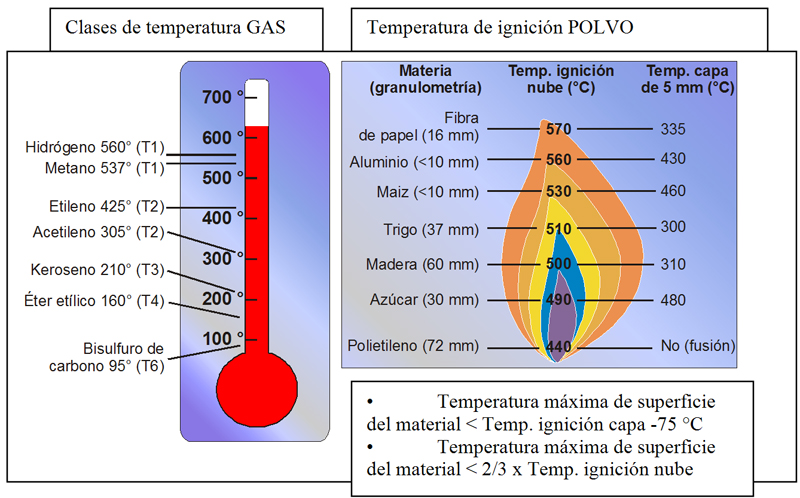

Temperature classes

The ignition temperature of a flammable gas or powder is the lowest temperature of a heated surface from which ignition of the gas / air mixture or steam / air occurs.

Thus, The maximum surface temperature of a material to be always lower than the ignition temperature of the surrounding atmosphere.