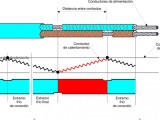

When cutting the wire between two contact points, will be in the cold regions Heater, one at each end of the heating cable run between the cutting point and the first contact of each end. The cut sections for cable Parallel PCB sound 600 mm for all lengths.

By applying voltage in conductors, heating conductor, receives this same tension between the contact points so, power per linear meter of cable is independent of the length thereof.

Typical applications

• Heating of pipelines and tanks, containing fluids such as heavy fuel oils, fat, paintings, waxes and other chemicals.

• Thawing cameras: together, doors, trays, drainpipes, antivaho, glasses, etc..

• Heating of reagent vessels and stills.

• Protection against freezing of water pipelines and valves

• To prevent the formation of condensation water in switch cabinets.

Main Features

• Compound-silicone based silicone elastomers

• braided Mesh tinned copper for continuous protection and socket Land.

• External dimensions: 7,5 x 5 mm for models WITHOUT Mesh Making Land and 8,5 x 6 mm for models with power Land • Color of outer sheath: Blue Transparent according to the model

• Supply Leads: Copper Nickel 2 x 1,5 mm²

• Heating: Alloy Nickel-Chrome

• Distance between contacts (Cut section): 600 mm for all lengths, except for the model that is CCP20T 1000 mm for all lengths.

• Maximum temperature exposure (cable disconnected): 180 °C

• Maximum circuit length: depending on model

• Single Phase Power 230 V ~

• If you want, order providing other powers may, voltage, etc..