The response time is a few seconds.

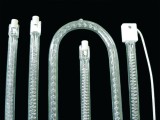

Besides getting excellent structural rigidity, the spiral type "porcupine" is designed to minimize emissions and maximize IR light emission, increased radiant efficiency and IR.

• Low thermal inertia.

• Made of clear quartz crystal

• Connection via R7screw.

• Low order, The tubes are manufactured to the customer, can vary its power, Voltage, length, etc..

Typical applications

• Preheating and heating.

• Secado.

• Polymerization.

• Heat Set.

• Cooking.

• Thawed.

• Tostado.

• Sterilization.

• Dehydration.

• Fusión.

• Sealed

Applications in industry:

• Vidrio.

• Papel.

• Plástico.

• Food.

• Pintura.

• Graphic arts.

• Textil.

• Caucho.

• Metal.

• Ceramics.

• Madera, etc.…

Special features

The tungsten filament used in these heaters is of the "porcupine" or star. It can operate at temperatures up 1500 °C, with an emission peak of Longitude de onda of approximately 1.6 mm.

The response time is a few seconds.

Besides getting excellent structural rigidity, the spiral type "porcupine" is designed to minimize emissions and maximize IR light emission, increased radiant efficiency and IR.

• Low thermal inertia.

• Made of clear quartz crystal

• Connection via R7screw.

• Low order, The tubes are manufactured to the customer, can vary its power, Voltage, length, etc..

Advantage

• Heating energy is transferred quickly to the object so that its surface reaches the curing temperature with a minimum heating of the support.

• Low thermal inertia.

• precise control and energy saving.

• heating on the surface and deep.

• Gran Quality in the finished product treated.

• Reduced plant size.

• No environmental pollution or harmful effects on food.